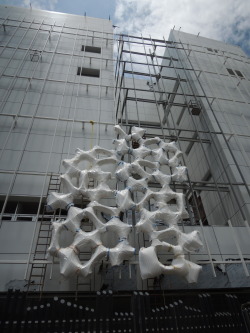

The 2500m2 facade at Torre de Especialidades is a 100m long, curved screen along Avenida San Fernando, a busy arterial in Tlalpan, in the southern quarter of Mexico City.* Funded by the Ministry of Health, the project is part of a 3-year, $20 billion investment into health infrastructure in Mexico. Prosolve was chosen by the hospital in part for its anti-microbial, de-polluting effect, as well as providing visual complexity, memorable in form, as a counter to the city's air pollution problem.

Project: Depolluting Quasicrystal Facade

Completion: April, 2013

Client: ICA, S.A.B. de C.V.

Structural Eng: Buro Happold New York

Material Testing: Kiwa MPA Bautest GmbH, TU Berlin, Fraunhofer IPA Stuttgart

Consultant: Joshua Socolar, Professor, Physics Department, Duke University

Project Size: 35,000m²

Size of Prosolve Facade: 2500m²

DEVELOPMENT

Prototypes for Torre de Especialidades were installed at our thermoforming factory in Ulm in April, 2012. A 1:1 scale patch was installed onto steel verticals to test the assembly and estimate installation times.

The patch is composed of 4 Mega Panels (clusters of 3-6 modules) taken from the top left corner of the facade in Mexico.

PROSOLVE 370e

3D Architectural Tiles

Prosolve370e is a decorative architectural module that can effectively reduce air pollution in cities when installed near traffic ways or on building facades.

The modules are coated with a superfine titanium dioxide (TiO2), a pollution-fighting technology that is activated by ambient daylight. Employing a unique configuration of this technology, the tiles neutralize air pollutants when sited near traffic or densely polluted conditions.

As a modification to existing architectural surfaces, prosolve370e essentially “tunes buildings” to respond better to their immediate environments.

Depolluting Technology

The modules are coated with a superfine titanium dioxide (TiO2), a pollution-fighting technology that is activated by ambient daylight. This is the nano photocatalytic version of conventional TiO2 commonly used as pigment and already known for its self-cleaning and germicidal qualities. It requires only small amounts of naturally occurring UV light and humidity to effectively reduce air pollutants into harmless amounts of carbon dioxide and water.

When positioned near pollution sources, the coated tiles break down and neutralize NOx (nitrogen oxides) and VOCs (volatile organic compounds) directly where they are generated.

The design of the tiles is generated to maximize the coating technology, achieving new levels of surface area and complexity, capturing omni-directional light where light is dense or scarce. The sculptural surfaces maintain an inherent synergy between design form and the molecular technology.

When positioned near pollution sources, the coated tiles break down and neutralize NOx (nitrogen oxides) and VOCs (volatile organic compounds) directly where they are generated.

The design of the tiles is generated to maximize the coating technology, achieving new levels of surface area and complexity, capturing omni-directional light where light is dense or scarce. The sculptural surfaces maintain an inherent synergy between design form and the molecular technology.

As a result, the modules incorporate an elegant technology, while remaining, formally, a decorative apparatus.

1

Combustion engines emit harmful toxins such as NOx and VOCs while running, and also emit VOCs, ozone and particulate matter while resting. 2A photocatalytic screen positioned between cars and people would trap and filter many of the harmful by-products of combustion engines.

Complexity and Modularity

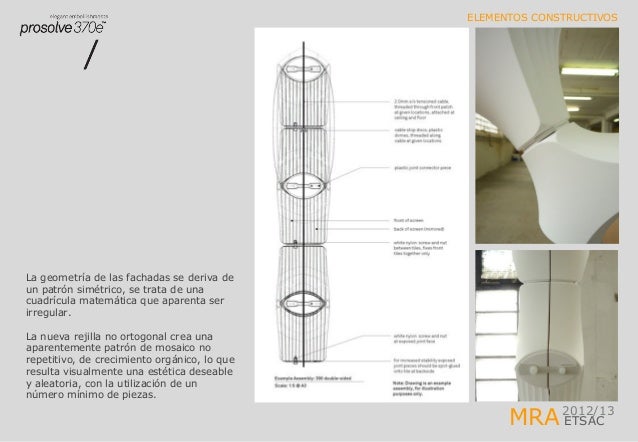

Derived from a five-fold symmetric pattern, the underlying substrate for the tiling is a mathematical grid that appears irregular, yet is made of few constituent parts.

The new, non-orthogonal grid creates a seemingly non-repetitive, tiled pattern, resulting in visual randomness, a desirable aesthetic that is typically achieved through bespoke design and expense.

The new, non-orthogonal grid creates a seemingly non-repetitive, tiled pattern, resulting in visual randomness, a desirable aesthetic that is typically achieved through bespoke design and expense.

The modularity of the system enables complex architectural shapes to be accessible, benefiting from economies of scale.

While the pattern resembles organic growth, the system is still composed with only two repeating modules.

Depolluting Facades

prosolve370e is proposed as a decorative facade module, with specifically-developed joints that are able to translate the pattern to standard, off-the-shelf, cladding equipment.

The tiles are made of a lightweight thermoformed fire-rated ABS plastic shell, joined with standard steel fixings.

As a decorative module, the tiles have potential to regenerate aged facades, ornament a modernist facade, or provide an appealing face to buildings which lack identity or community significance.

Proposals for installations have ranged from carparks to mixed-use/housing to hospital facades.

The tiles are made of a lightweight thermoformed fire-rated ABS plastic shell, joined with standard steel fixings.

As a decorative module, the tiles have potential to regenerate aged facades, ornament a modernist facade, or provide an appealing face to buildings which lack identity or community significance.

Proposals for installations have ranged from carparks to mixed-use/housing to hospital facades.

1200 Series Assembly

The 1200 series is intended for large-scale, architectural applications. Each tile is approximately 1.1sm.

The tiles can be installed as single-sided, or with corresponding backs. The system also includes an end piece which can be repeated at the edges of the pattern to resolve edge and corner conditions.

The tiles can be installed as single-sided, or with corresponding backs. The system also includes an end piece which can be repeated at the edges of the pattern to resolve edge and corner conditions.

Some training for the assembly team on the Mega Panels. First panel assembled, wrapped and ready for installation.

Installation progress:

Sources: http://prosolve370e.com/pr_torre.htm

http://elegantembellishments.tumblr.com/

http://es.slideshare.net/FerminBlanco/prosolve-370e-v-97-03

http://www.construdata.com/Bc/Construccion/Noticias/fachadas_inteligentes_contra_la_contaminacion.asp

No hay comentarios:

Publicar un comentario